Micro-Epsilon thickness measurement

Micro-Epsilon makes optical sensors for a variety of applications. Micro-Epsilons systems division utilizes the sensors and develop and manufacture thickness and thickness profile measurement systems for the process industry. Prodaptor cooperates mainly with the systems division. If you are located in northern Europe and are interested in sensors for distance, profile, pressure, color or temperature, please go to Sensotest homepage.

Micro-Epsilons thickness systems can handle material thicknesses from parts of a millimeter up to 400 mm and widths up to many meters. Material temperature ranges from room to red-hot, over 1200°C.

The design can be of C-frame or O-frame type, edge, center, multi-track and/or scanning.

The systems can handle specular surfaces, surfaces with scale, oil, or other debris. Tilted material and bad flatness can also be compensated for.

Compared to radiometric types, optical thickness gauges are safe, flexible, insensitive to alloy variations, fast and are more economical. For most applications, accuracy and precision is also better.

The powerful software is configurable and allows for system calibration and status information such as gauge and process capability data at any time.

Read more about Micro-Epsilons thickness gauges here.

Partners

KELK

KELK designs and manufacture measurement equipment in steel and metal industry. KELK is well established, a Canadian company who has supplied precision equipment since the early 50's and is recognized for the highest accuracy and reliability in the market. The measurement systems are based on optical methods and strain gage load cells.

ACCUSPEED- Non-contact Speed and Length Measurement

Accuspeed is a Laser Doppler-based system that measures the speed and length of moving materials in rolling mills. Accuspeed has a better accuracy than any other Laser Doppler based systems on the market and can handle a stand-off distance up to 3.5 meters.

There are two models of Accuspeed, for cold and hot applications. The units are rugged and do not require any additional protective housings, which saves space and time at service.

The cold version is passive and only an optic fiber and pressurized air need to be connected to the measurement head. No cooling water is required.

The Accuspeed system is used for quality assurance, crop-optimization, and mass-flow control. Thanks to the reliability, the system has the best life-time economy on the market. Read more about Accuspeed here.

ACCUBAND - Strip Width Measurement

KELK designs and manufactures width gauges for both hot and cold applications. The gauges are stereoscopic which adds accuracy and compensates for strip hops and pass-line variations. For hot application, the system operates based on IR. Backlight is required only when the material temperature is lower than 600 degrees (Celsius). For cold application, the system is compact, has no moving parts, and has LED front lights, which brings low maintenance cost to customers. There are three reasons why Accuband width gauges are outstanding; accuracy, long lifetime, and lower maintenance cost. Accuband width gauges have outperformed competition in numerous installations all over the world and are used in a large variety of applications, Crop Optimization System being an important one. Read more about ACCUBAND here.

ACCUCROP - Transfer Bar Crop Optimization Close Loop System

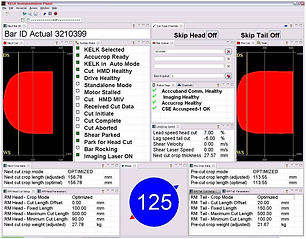

ACCUCROP is a sophisticated software developed over many years. Together with ACCUBAND Strip Width Gage, ACCUSPEED Laser Velocimeter, and Line Scan HMD (Hot Metal Detector), KELK Crop Optimization Closed Loop System controls the shear cut and guarantees the transfer bar cut accuracy.

KELK Crop Optimization System creates an image of the transfer bar, optimizes bar cut line, tracks the bar, and control/synchronize the shear cut.

Thanks to the accuracy of the measurement gauges, the cut can normally be placed with a precision of a centimeter. So material is saved for every coil.

Over 120 hot strip mills are saving material and production time already. If you are not convinced yet, contact us for a free payback calculation based on your own production. Here is further information.

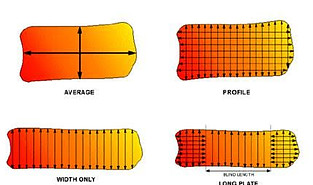

ACCUPLAN - Plate Outline Measurement

ACCUPLAN is a measurement system that is used for automatic mill control in automated mills or helps the rolling mill operators to optimize the plate shape and size during rolling for manually operated mills. The gauge is installed above the line and sees through steam. The shape is calculated to millimeter accuracy even at full production speed. For further information, go to KELK:s homepage.

Rollmax Load Cells

Rollmax Load Cells are manufactured as Washers, Discs, Slabs or T-blocks and have a unique 5-year warranty. The design of KELK Rollmax Load Cells can be customized in different ways depending on mill mechanical structures and applications. Find more information here.

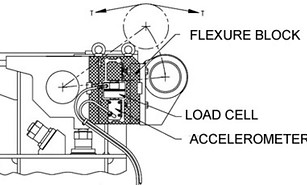

Tension Measurement

KELK Tensiometers are used to measure a wide range of tension in cold rolling mills and processing lines. For lower tension applications, such as processing lines, KELK Monobloc Tensiometer Transducer is used. For higher tensions such as tandem cold mills, KELK offers Tensiometer Load Cell Assembly in single or dual range. KELK Looper Load Cell Assembly is designed to measure load applied to interstand looper rolls in hot strip mills and has a 20 times overload capacity. The design of KELK load cells can be customized in different ways depending on mill mechanical structures and applications. Details can be found here.